Our view at Stack - Pipedrive is a robust CRM platform, offering automation, contact data collection, webhooks, AI-powered sales assistant, email communications, email marketing, and customisable sales pipeline workflows.

Efficient operations are the backbone of any successful business, driving everything from cost savings to customer satisfaction.

When managed effectively, operations can streamline workflows, reduce waste and help your business stand out.

In this article, you’ll learn what operations management is and why it’s essential for any organization aiming for sustained growth. You’ll discover the core methodologies and skills needed for better operations alongside a step-by-step process to implement effective operations management in your business.

What is operations management?

Operations management definition: the practice of organizing and optimizing all processes involved in producing goods or delivering services.

Operations management helps businesses convert resources – like labor, materials and technology – into high-quality products or services more effectively.

Operations affect nearly every aspect of a business, from day-to-day management to long-term strategic planning, improving efficiency while reducing waste.

With such a wide-reaching goal, the functions of operations management cover multiple elements, including:

-

Inventory management. Do you have the right amount of raw materials and finished goods on hand? Insufficient stock prevents you from meeting customer demand, while too much can lead to unnecessary storage costs and wastage.

-

Project management. Every operation is a series of smaller interconnected projects with various subtasks, processes and objectives. Properly managing each project contributes to the operation’s overall efficiency.

-

Quality control. Any products or services you produce need to meet (and ideally surpass) your customers’ expectations. A structured quality management process helps identify and resolve potential issues before they reach the customer.

-

Workflow management. Control and optimize each operation step to be as efficient as possible. Streamlined workflows improve productivity and reduce costs, allowing you to operate smoothly and quickly respond to changes.

-

Forecasting. When you can predict customer demand, you avoid issues like overproduction or running out of stock. Using historical data, analyzing market trends and talking with your customers, you can accurately estimate future requirements and plan accordingly.

-

Risk management. Hope for the best, but prepare for the worst. Operations managers assess potential risks that could disrupt processes (such as supply chain delays or equipment failures) and create contingencies to protect business operations.

What’s the difference between supply chain and operations management?

While both functions share similar components and goals for optimizing processes with increased efficiency, operations management operates at a high level to improve all of a business’s processes. Supply chain management is more concerned with the flow of products across multiple businesses, from raw materials to dispatched goods.

Core methodologies in operations management

Using a proven framework to improve operations aligns your processes with best practices and creates a more consistent approach across the organization.

Here are some of the more popular methodologies used in business operations management.

Six Sigma

Six Sigma is a collection of tools and techniques for reducing defects and variability. The DMAIC (define, measure, analyze, improve and control) framework helps you systematically achieve more consistent, high-quality results.

For example, a car manufacturer might use Six Sigma to minimize defects in the production line. The DMAIC process could identify the cause (e.g., operators using different settings) and update the procedures for improved standardization.

Lean management

Lean management aims to identify and eliminate any part of your operations that doesn’t contribute value to the customer or end user. Originating from Toyota’s production system, Lean emphasizes continuous process improvement and minimizing waste for a more efficient workflow.

For instance, a SaaS company might discover that its customer support teams take too long to resolve specific issues. It could then find and remove any unnecessary steps in its support procedure.

Theory of constraints

Theory of constraints (TOC) focuses on finding and managing the “constraint” or bottleneck that limits overall system performance. By addressing the bottleneck, operations managers can increase throughput and optimize productivity.

For example, an e-commerce company may notice regular delays in shipping orders. With TOC, it identifies the bottleneck (e.g., packing goods for dispatch) and allocates more resources to that process.

Business process redesign

Business process redesign (BPR) encourages you to ask what your processes would look like if you had the opportunity to start from scratch. Rather than making minor adjustments to existing workflows, BPR often involves rethinking the fundamentals of each step and redesigning the entire process.

For instance, a consultancy might use BPR to overhaul its onboarding process, replacing a tedious paper-based system with a new digital onboarding platform.

Why is operations management important?

Operations management plays a central role in the success of any organization. By optimizing every part of your production or service process, your business will be in a better position to deliver a top-quality solution and gain a competitive edge.

For example, a recent study found that effective operations management practices boosted profitability, yielding even better results when combined with good supply chain management.

Here are four specific benefits that come with a strong operations management program.

1. Improved efficiency and reduced costs

Operations management aims to maximize the use of all resources, such as labor, materials and time. Streamlining workflows and reducing waste can cut costs without negatively impacting productivity.

For example, by carefully planning inventory levels and production schedules, you can avoid overstocking and lower storage expenses, freeing up capital for other business needs.

2. Increased customer satisfaction

When you can produce better-quality products at a lower cost, you’re more likely to exceed expectations, fostering trust and customer loyalty. Optimizing each step of the production and delivery process results in faster, more reliable service and reduces the chance of errors.

Rigorous quality assurance measures help identify and resolve potential issues so that only compliant products reach your customers. Streamlined workflows and improved inventory management also help you adjust to any changes in demand, minimizing delays and maintaining customer satisfaction.

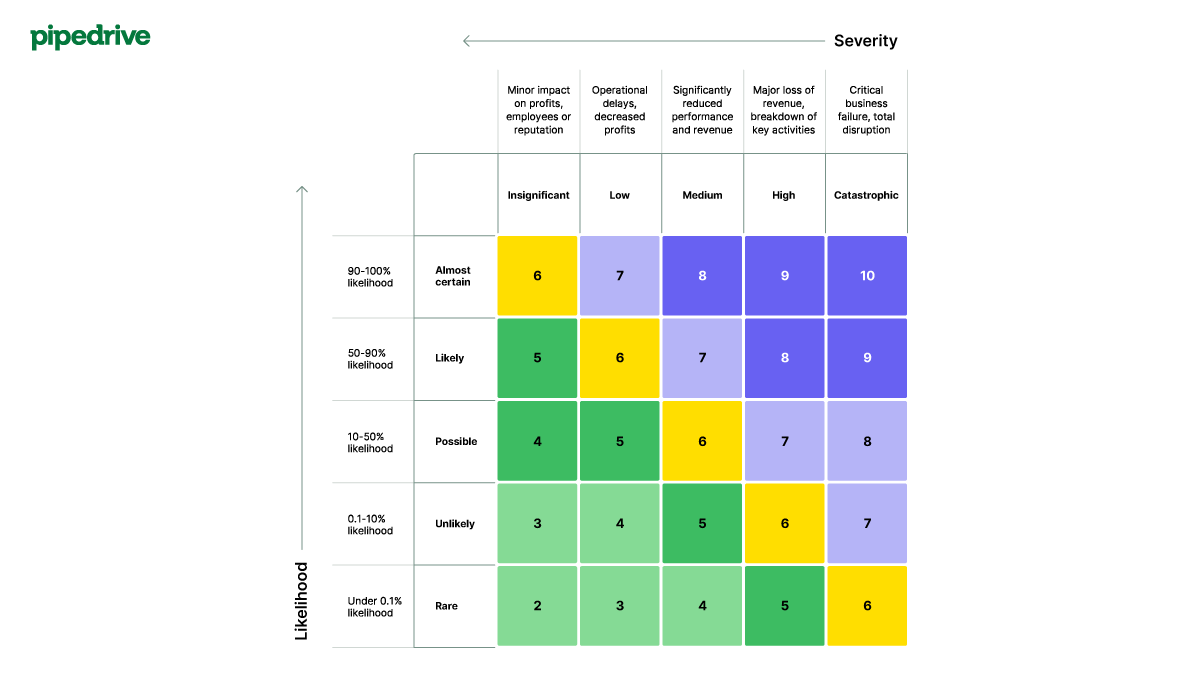

3. Better risk management and resilience

A big part of operations management is identifying potential risks and developing mitigation strategies. You can minimize downtime and protect your business’s stability by using integrated risk management (IRM) to assess and prepare for possible disruptions – such as supply chain delays or sudden shifts in demand.

For example, diversifying suppliers and building flexible workflows enable you to adapt quickly to changes, ensuring continuity even during unexpected events.

Operations management also emphasizes creating contingency plans, which empower businesses to respond proactively to challenges and stay resilient in a fluctuating market.

Recommended reading

What is production management? The definitive guide for business owners and prospective managers

Key skills for effective operations management

Good operations management requires a unique blend of skills, from technical expertise to strong interpersonal abilities.

The following skills enable the operations management team to oversee every aspect of the business’s processes and keep them running smoothly.

1. Problem-solving

Operations managers often face challenges such as production bottlenecks or supply chain disruptions. Strong problem-solving skills can help you identify the root cause of these issues, devise appropriate solutions and implement them quickly to minimize disruptions.

For example, if a piece of manufacturing equipment fails unexpectedly, you might need to adjust your workflow to keep production on schedule.

Problems may be less obvious in cases such as gradually increasing manufacturing costs or turnaround times. Strong troubleshooting skills enable you to dig deeper, analyze patterns and identify underlying causes that may not be immediately apparent.

2. Stakeholder management

Operations cover so many different aspects of your business that operations managers must be able to work with all various stakeholders, including other department heads and front-line staff. Good communication skills ensure that everyone involved understands expectations, timelines and any changes to the process.

Similarly, strong relationships with suppliers and other key partners improve collaboration and can help you negotiate better terms or resolve issues quickly.

3. Data analysis and decision-making

Operations managers rely on data. You need to know what’s happening in your business to make the right decisions, be it past sales data, customer demand, inventory levels or production rates.

By analyzing data regularly, you can forecast future demand and make adjustments to improve efficiency, such as sourcing extra raw materials from different suppliers or adjusting production schedules.

4. Attention to detail

Even the smallest detail can significantly impact your operations. Operation managers must closely monitor each process stage to catch issues before they escalate.

For example, in manufacturing operations management, you should create specifications and ensure every product meets them. In service industries, it might mean verifying customer order details to avoid mistakes that could cause delays or upset customers.

What operations managers do

Operations managers’ responsibilities vary depending on the industry and business type.

However, if you’re taking on the role of operations manager, there are some core responsibilities that you’ll likely be in charge of, such as:

-

Overseeing production or service delivery. Check that production or delivery services are on schedule, within budget, at the required quality level and to the customer’s satisfaction.

-

Coordinating different departments. Work with other departments (e.g., sales, marketing and finance) to improve performance and align resource management and timelines with company objectives.

-

Managing supply chains and inventory. Forecast future demand (based on sales data and market trends), build strong supplier relationships and monitor inventory to ensure materials and products are available when needed.

-

Implementing and monitoring quality standards. Set quality standards and perform regular checks to confirm you’re consistently meeting expectations. Address any quality issues promptly and take steps to prevent recurrence.

-

Creating and optimizing processes. Design business management processes or use methodologies to improve your existing processes for enhanced productivity, reduced waste and increased profitability.

In short, operations managers combine the resources, people and processes that make up a business, ensuring each element works appropriately and contributes to company goals.

Recommended reading

The Five Key Responsibilities of Sales Operations Managers

How technology is transforming operations management

Technology has become an integral part of modern operations management. With the right tools, operations managers can drive continuous improvement with data-driven insights, high precision and informed decision-making.

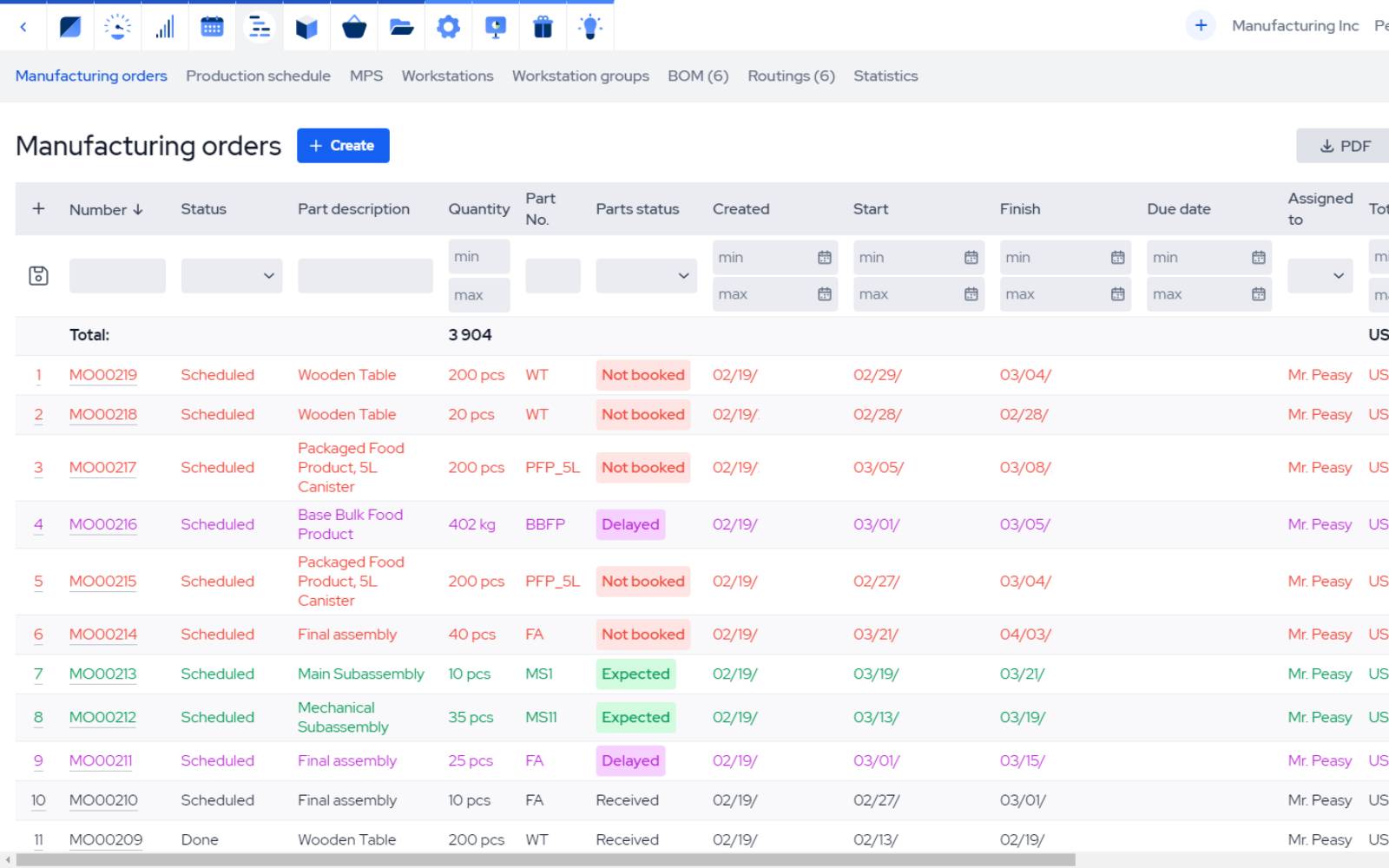

Enterprise resource planning (ERP) systems

ERP systems unify data from different departments (like finance, inventory and HR) into a single platform, giving operations managers a comprehensive view of business performance. With real-time data on inventory, production schedules and staffing, ERPs help you use resources effectively to improve efficiency and cut costs.

For example, MRPeasy is a cloud-based ERP solution that gives operations managers complete control over production planning, inventory management and procurement.

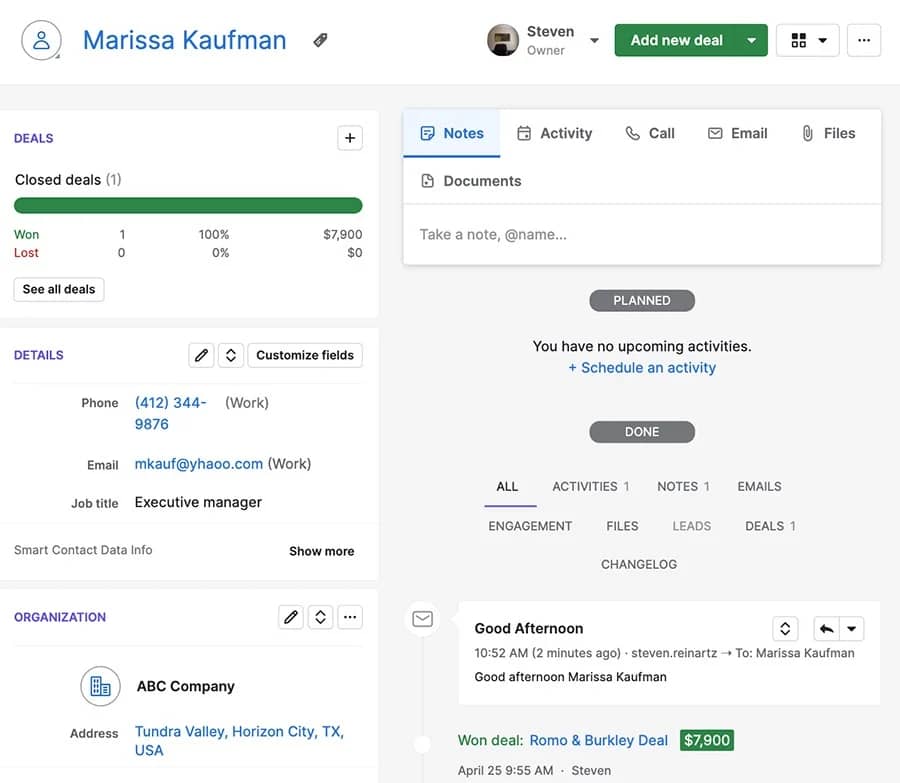

Customer relationship management (CRM) systems

CRM software provides valuable insights into customer behavior and preferences, such as previous purchases or communication. Operations managers can use this data to align production with customer demand, reducing stockouts and enhancing customer satisfaction.

By centralizing customer data, CRMs like Pipedrive improve collaboration between your sales, marketing and operations teams and update you on upcoming campaigns or new product launches.

For example, AGT Engineering and Operations Services increased revenue by 161% after integrating Pipedrive. The company can now easily access past data to forecast future market trends.

Data analytics and business intelligence (BI) tools

Data analytics platforms offer real-time insights into operations metrics, such as production rates and delivery times.

Operations managers can use this information to make on-the-spot decisions to optimize performance. In manufacturing, data analytics can predict equipment maintenance needs, reducing downtime by addressing issues before they become serious.

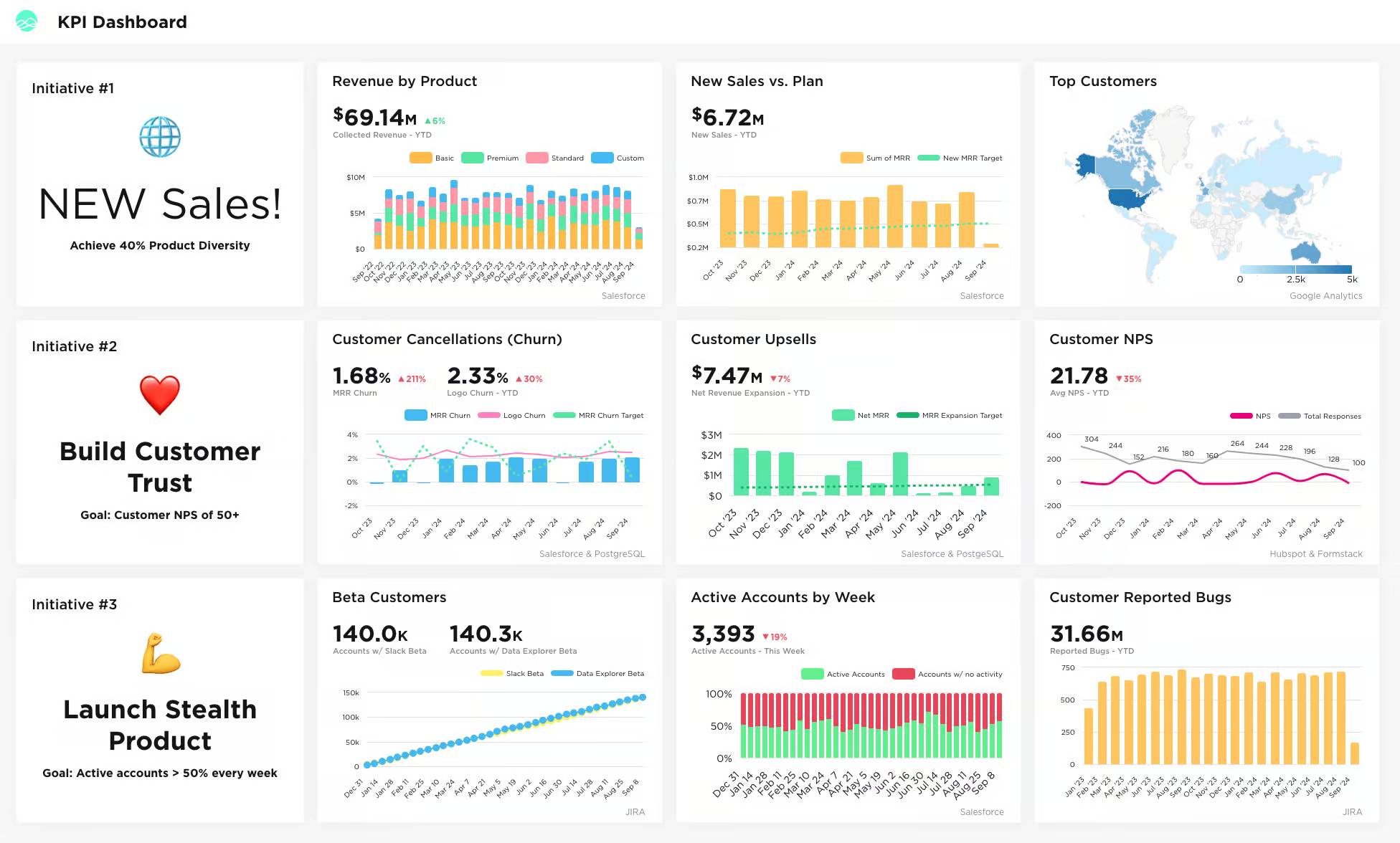

Similarly, BI reporting tools can analyze historical data, revealing trends that help operations managers forecast demand, identify bottlenecks and streamline workflows. Software like Grow can integrate with your CRM to create BI reports in visual dashboards like this one:

Automation and artificial intelligence (AI)

Many of the tools mentioned, such as CRM and ERP software, already use automation and AI to improve decision-making.

For instance, AI-powered CRM systems can analyze customer data to predict purchasing behavior. Workflow automation frees time from repetitive admin tasks so operations managers can focus on more strategic work.

However, your use of AI and automation doesn’t have to stop there.

For example, you can implement AI in manufacturing for automated quality inspections. Machine learning algorithms can detect defects in real time by analyzing product images or sensor data so you only pack and dispatch items that meet your standards.

In a recent case, IBM leveraged AI and automation while working with an automobile manufacturer. The process helped detect and fix issues before a vehicle left the premises, reducing defects and downtime.

How to implement an operations management strategy

Implementing an effective operations management strategy requires careful planning and a commitment to continual improvement.

Here’s a step-by-step guide to help you build an operations strategy for more effective procedures.

Step 1. Define clear goals and objectives

Start by defining success for your operations management strategy. Common goals include growing production efficiency, reducing costs, increasing customer satisfaction or improving product quality.

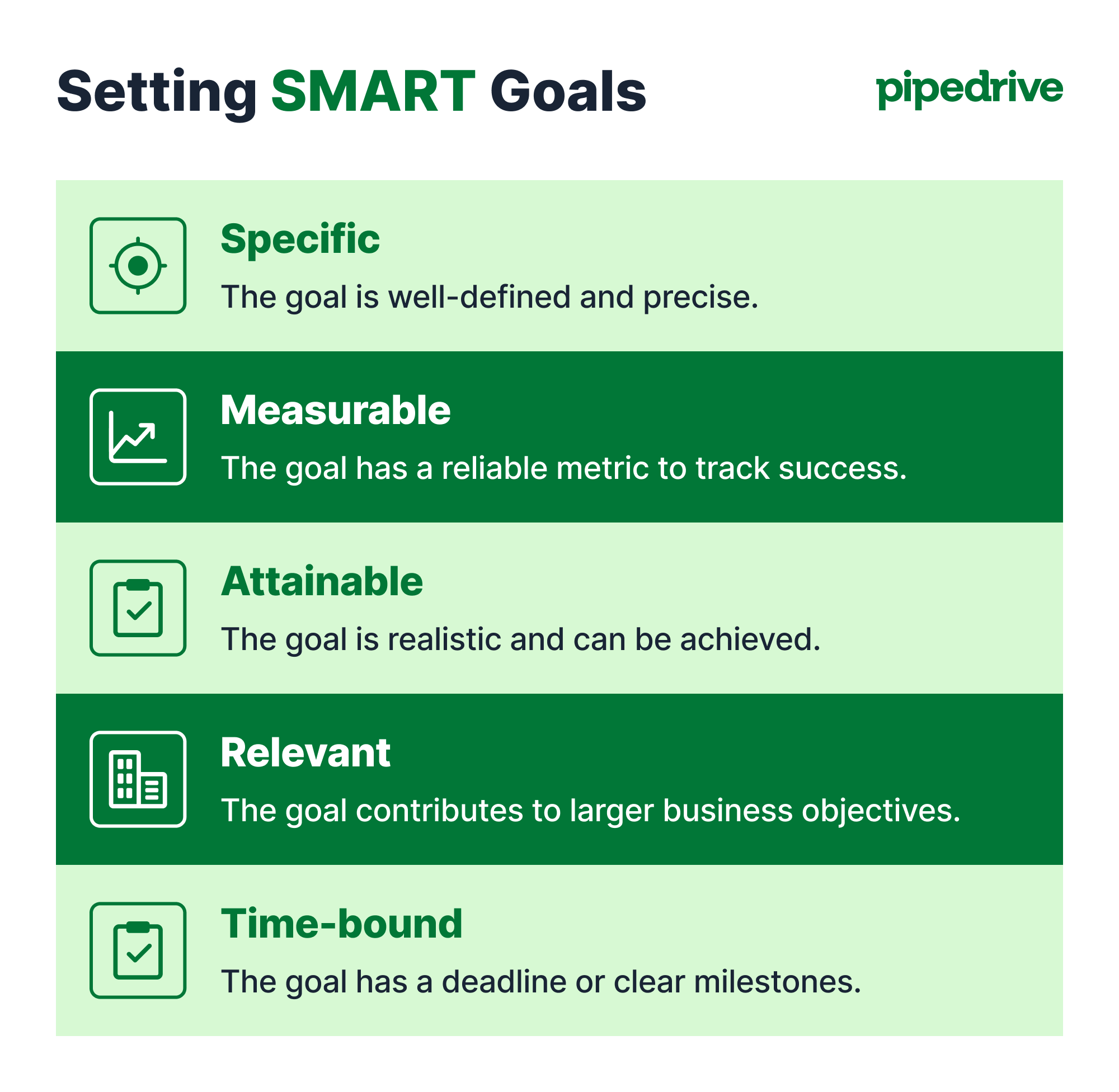

Use the SMART framework to create clear and meaningful goals.

For example, a manufacturing company might set the goal of reducing production time by 20% over the next quarter. The goal is specific, measurable (20%), attainable (based on existing resources), relevant to the company’s goals and time-bound (three months).

Step 2. Analyze current processes and identify gaps

The next step is to conduct a process audit. Examine your existing workflows to understand how each part of the operation currently functions. Look for any obstacles, redundancies and inefficiencies.

Map each input (such as materials, human resources and technology) to its output (finished goods or services) to understand how resources flow through the process and where you can improve.

For example, our manufacturing company might discover it spends a lot of time on product inspection because of manual quality checks.

Tip: Use the data from your ERP or CRM systems to identify patterns in the different processes and discover specific opportunities to optimize your operations.

Step 3. Choose an appropriate methodology

Instead of relying on trial and error to reach your goals, using a recognized framework increases your chances of success by providing a structured, proven path to improvement.

Choose a framework or methodology that aligns with your goals. If you’re trying to eliminate wasteful steps in your process, you might want to use the Lean management methodology. Six Sigma might be more appropriate if your objective is to improve quality and consistency.

These strategies aren’t one-size-fits-all, so you’ll likely need to tailor your chosen methodology to fit your industry, company size and specific challenges.

Lean management helps eliminate waste and optimize workflows in our manufacturer’s case. The company can use the framework to identify the exact activities (like redundant inspections) it can reduce or replace.

Step 4. Design and document new workflows

Once you’ve chosen an appropriate methodology, apply it by designing and documenting new workflows. Create a detailed process map clearly outlining each step and the necessary resources.

The goal is to establish a streamlined, optimized workflow that removes any inefficiencies or bottlenecks you’ve identified in your analysis. Document each step to ensure consistency and provide a training reference to help your team follow the new process.

In our manufacturer example, the company could redesign the workflow to introduce automated quality inspection equipment and document the change in a new standard operating procedure (SOP).

Step 5. Allocate resources

With new workflows in place, you need the right resources to support each step adequately.

Assess the manpower, equipment, budget and materials required for each part of the process. Allocate resources based on your updated workflows, ensuring all teams have what they need to do their job.

For example, if a new workflow requires additional machinery or specific tools to maintain efficiency, see that they’re available to the relevant personnel. Proper resource allocation helps prevent delays and creates a solid foundation for business strategy implementation.

In the case of our manufacturer, the company would need to invest in new quality-inspection equipment.

Step 6. Implement the right technology

Choosing and deploying the right information technology tools is critical to supporting your new workflows and achieving your goals.

Implement tools like ERP systems, CRM software or data analytics platforms to centralize information and improve efficiency. Pay particular attention to technology that aligns with your defined goals and priorities.

Introduce the technology gradually to avoid disruption. Test it in stages to confirm it works smoothly with your existing tools and processes.

For example, a CRM is crucial if your goal is to improve customer satisfaction and sales forecasting. Meanwhile, data analytics tools can provide valuable insights into inventory turnover or production rates.

Our manufacturer could integrate an ERP system to monitor production data and track the results of its new automated inspection process.

Step 7. Train your team

With workflows, resources and technology in place, focus on training your team so everyone understands any changes to their responsibilities and is confident in their ability to carry out new processes.

Conduct training sessions or workshops for employees to learn the updated workflows, understand their roles and familiarize themselves with any new technology.

To help employees adapt quickly, provide hands-on training and easy access to support resources such as guides or videos. Encourage questions and gather feedback to address challenges early on and improve the transition.

For example, our manufacturing company could hold training sessions on properly using automated inspection equipment and ERP software.

Download your guide to managing teams and scaling sales

The blueprint you need to find a team of superstars and build a strong foundation for lasting sales success

Step 8. Monitor performance and optimize

Once the new processes are running, monitor performance to confirm they deliver the expected results. Track the key metrics tied to your goals from step one, such as production speed, cost savings or quality improvements.

Review this data regularly to identify areas where adjustments could lead to further efficiency gains. Continuous optimization allows for small, iterative changes that can have a big impact over time, helping your operations stay agile and responsive to shifting demands.

In our manufacturer’s case, the operations team would track the production process using the ERP system. Depending on the results, it might look for other ways to reduce production time. If the team has sufficiently addressed that area, the process can restart with a new goal or objective.

Final thoughts

Every business has processes – or operations – that need to happen to create value. By properly evaluating and managing your operations, you can identify opportunities to maximize workflows, use your resources more efficiently and exceed customer expectations.

Operations management professionals can drive continuous improvement with the right tools, strategies and initiatives.

Begin by examining your current practices, exploring potential enhancements and setting clear operational goals. Even minor adjustments can yield significant and lasting benefits, helping your business practices stay agile and competitive.

If Pipedrive is of interest and you'd like more information, please do make contact or take a look in more detail here.

Credit: Original article published here.