Our view at Stack - Pipedrive is a robust CRM platform, offering automation, contact data collection, webhooks, AI-powered sales assistant, email communications, email marketing, and customisable sales pipeline workflows.

Managing inventory can be tricky for any operation. Order too much, and you have overstocks that consume space and tie up cash. Order too little, and you risk running out of products and disappointing customers. Just-in-time (JIT) management can help you tackle your stock challenges and more.

In this article, you’ll learn what JIT management is, the benefits of using it and how you can implement a JIT system for your business.

What is JIT management?

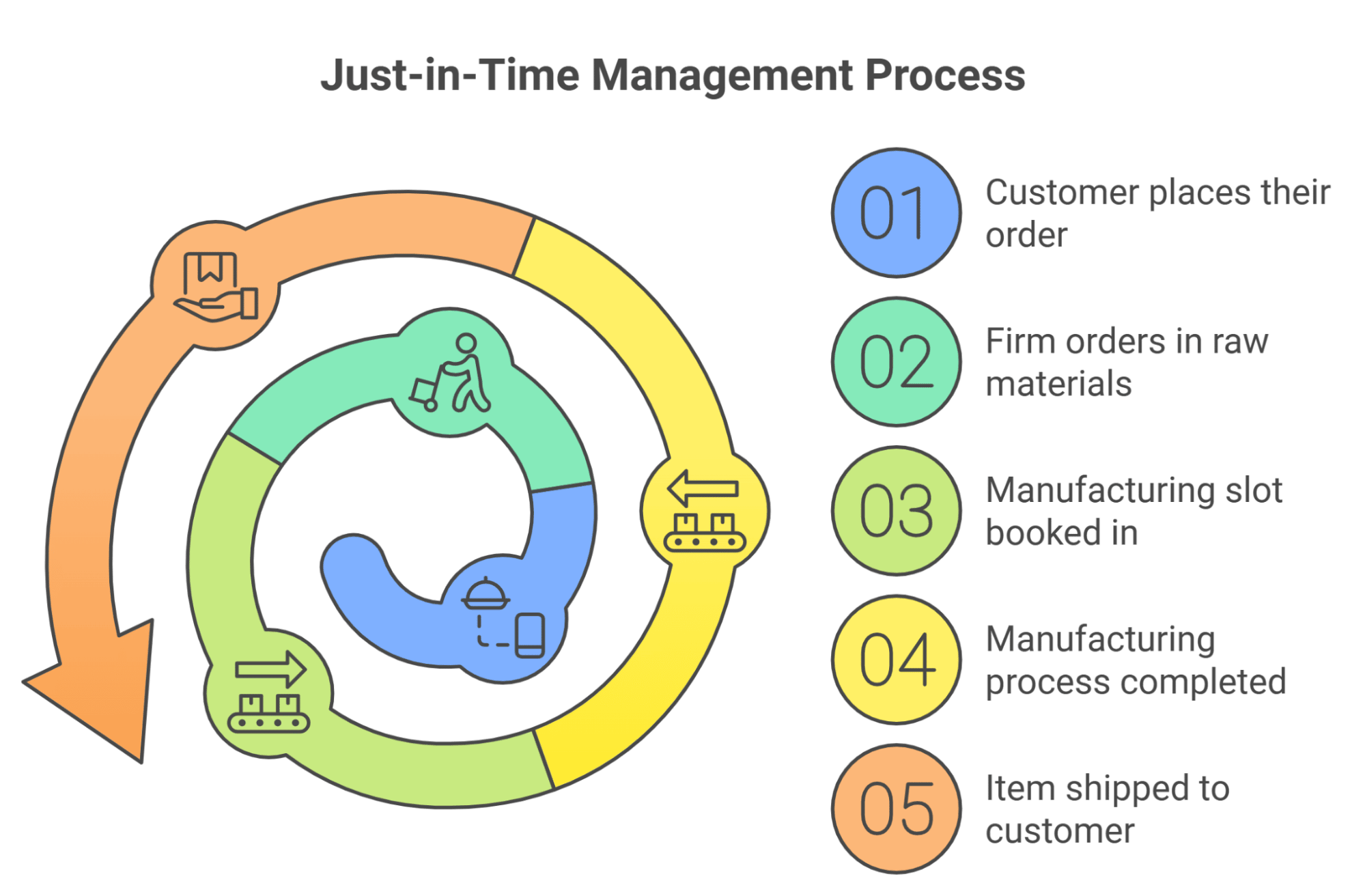

The just-in-time methodology manages stock levels so that you only order from your suppliers when your production team needs raw materials or your dispatch team needs to fulfill a customer order.

By holding only minimal inventory, you free up cash within the business. This allows you to quickly scale up purchasing to meet market changes, such as increased demand for specific products.

JIT management follows the Toyota Production System pioneered by the Japanese automotive giant. It aims to reduce waste, keep customers happy and save time and money – an approach known as lean manufacturing.

Think of JIT as an offshoot of lean manufacturing that focuses on timing: getting exactly what you need, exactly when you need it.

Imagine a bakery business owner specializing in high-end, fully customizable wedding cakes. Instead of building stockpiles of cocoa, icing sugar and flour, they only order the exact ingredients required for each cake request. They then bake the cake, ensure it meets quality standards and deliver it to the customer.

The JIT approach isn’t just for manufacturers – wholesalers and retailers also use it. It’s a step-by-step process that involves waiting for customer orders before buying stock from suppliers, reducing the need to store excess inventory.

A JIT inventory system works well if you want to avoid overproduction and overstocking, streamline your production processes and reduce inventory storage space to increase capacity for other operations.

Recommended reading

What is production management? The definitive guide for business owners and prospective managers

What are the benefits of just-in-time management?

A just-in-time (JIT) inventory management system offers many benefits for businesses, a major one being healthier cash flows. You have bigger budgets for business growth because you don’t tie up your working capital in excess stock.

Other significant benefits of JIT include:

-

Greater profitability. By spending less on inventory, you save on storage, insurance and handling costs. Plus, your sales and marketing teams can focus on pushing the high-demand products you’ve identified, maximizing return on investment.

-

Enhanced productivity. Your team will spend less time receiving stock and dealing with storage logistics. Smoother fulfillment workflows increase your capacity and enable faster turnaround times.

-

Less waste. Just-in-time ordering means you only make or stock what you need, addressing common business pain points like disposal costs and limited storage space.

-

Higher-quality products. Smaller batch sizes and more manageable runs mean quality issues are easier to spot and fix, preventing production disruptions and high customer return rates.

Success with the JIT methodology depends on building strong, reliable supplier relationships. Your suppliers work to your production and delivery schedules so materials and products arrive when needed.

Precise timing and low inventory levels allow you to quickly change what you make or stock, meaning you can respond faster to market changes and new opportunities.

Recommended reading

Product management for SMBs: a complete guide

How to implement a just-in-time inventory management system for your business

With careful planning and execution, the right just-in-time system will significantly improve your business performance.

Here are five steps to successfully implementing a JIT management strategy:

1. Assess your current inventory levels and customer demand

Start by auditing your inventory to see where you’re wasting money and storage space. Take the following actions:

-

Check for overstocks. Look for items taking up space without generating sales revenue, as these drain your capital.

-

Identify slow-moving stock. These products don’t sell quickly and risk becoming obsolete before you find a buyer.

-

Remove obsolete inventory. Free up space by clearing out products that no longer serve a purpose.

-

Use stock aging reports. Focus on selling older stock first to clear storage space and avoid disposal costs.

This process lays the groundwork for a leaner, more efficient inventory system.

Next, review historical sales data to spot patterns in demand, such as peak periods when stockouts or overstocks are most likely. You’ll also see which products are constantly in demand and need the most reliable supply chain.

By pinpointing which stock you’re holding too much or not enough of, you can adjust your stock levels to match your customers’ needs. This knowledge makes the transition to JIT smoother and more effective.

Note: Just-in-case manufacturing is, in many ways, the exact opposite of just-in-time manufacturing, as it focuses on building inventory to account for swings in demand and supply chain disruptions. Many enterprise companies take a just-in-case approach to maximize sales opportunities and minimize the risk of stockouts.

2. Set KPIs for JIT integration

Key performance indicators (KPIs) are metrics that can monitor whether your efforts are successful. Pick ones for your JIT system that match your goals to help you measure progress and uncover areas for improvement.

Useful metrics you could track as part of your JIT management include:

|

KPI |

Benefit |

|

Inventory turnover rate |

See how efficiently you manage inventory so you can reduce holding costs |

|

Order fulfillment cycle time |

Tracks how fast you’re servicing customer orders, which impacts the customer experience |

|

Days of held inventory |

Highlights how long stock remains in storage to spot opportunities to cut back on excess inventory |

|

Stockout rates |

Shows how often stockouts happen so you can spot demand-supply mismatches |

|

Defect rates |

Monitors quality issues, which affects production efficiency and customer satisfaction |

Setting and tracking clear targets keeps you focused and helps you find new ways to optimize and improve your JIT inventory management system.

Download Your Guide to Sales Performance Measurement

The must-read guide for any sales manager trying to track, forecast and minimize risk. Learn how to scale sales with data-backed decisions.

3. Prepare for JIT implementation

The next step is to prepare your company and its suppliers for the implementation of JIT.

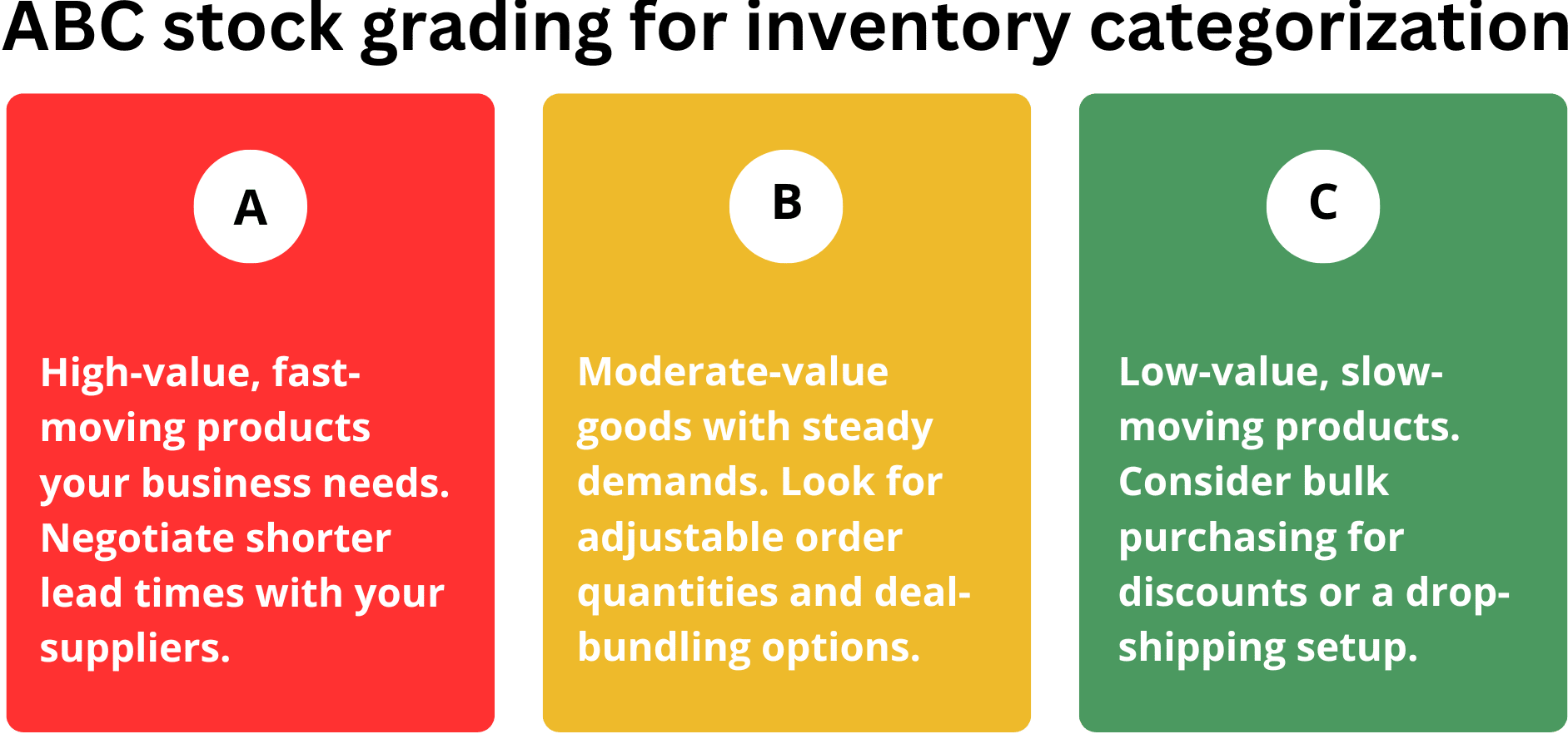

First, categorize your inventory based on its importance.

-

A items: high-value, fast-moving raw materials you need on demand. Set up a robust delivery arrangement or explore vendor-managed inventory, where your supplier monitors your stock and replenishes it when it runs low.

-

B items: moderate-value goods with steady demand. Approach suppliers to see if they’ll allow you to adjust quantities based on customer demand. Ask for bundling deals where you receive a discount on B items related to A items.

-

C items: low-value, slow-moving products. Consider phasing them out, bulk purchasing to achieve lower prices or a drop-shipping arrangement where your supplier fulfills the order.

Second, find bottlenecks stopping you from manufacturing or delivering as fast as possible.

Start by reviewing your entire supply chain. Check each supplier’s lead times, on-time delivery rates and defect rates, as these can disrupt your JIT system. Stick with reliable suppliers and look for new partnerships to replace undependable ones.

Look internally for inefficiencies. Delays in approving supplier orders and frequent equipment breakdowns can halt production or shipping. Consider holding safety stock for high-demand items and critical production materials to avoid costly stoppages.

Third, share your demand forecasts with new and existing suppliers, especially those providing your A items. This will help them match your production schedules. Negotiate the best terms you can, as smaller, frequent orders often cost more per unit. Run trial orders with new suppliers to assess product quality and delivery reliability before committing.

Optimizing your internal processes and partnering with reliable and flexible suppliers give you a robust foundation for meeting customer demand on quality and timescales.

4. Change your work processes for JIT

Switching to JIT operations management involves significant adjustments to your current work processes.

Here are six ways you can streamline your operations to maximize the benefits of JIT:

-

Simplify stock storage. Streamline how you receive and store raw materials so they move straight into production or designated storage space. You’ll reduce handling time, cut labor costs and lower damage or loss risks.

-

Switch to frequent, smaller orders. Order smaller batches of products more often, consistent with how you’ve ABC-graded them, to prevent overstocking and ensure items are available when needed.

-

Let customer demand guide ordering. Base your purchasing decisions on real-time sales data, not just sales forecasts. You’ll prevent costly supply-demand mismatches and fulfill orders quickly.

-

Improve inventory control. Track inventory movements in real time to gain complete visibility of stock levels, spot errors like misplaced stock faster and avoid stockouts or delays.

-

Implement stock-level alerts. Set up automatic notifications to alert manufacturing, delivery and sales teams to low stock levels, prompt timely reordering and prevent disruptions to production and fulfillment schedules.

-

Make quality control a priority. Implement quality checks at every stage of production and fulfillment to reduce product defects, save time on reworks, meet delivery deadlines and reduce the risk of returns.

The above processes will streamline your business operations by improving productivity and efficiency, helping you deliver better customer service.

5. Monitor your KPIs and look for improvements

Keep a close eye on the KPIs you chose to measure at the outset of your JIT implementation program. Review them regularly to quickly spot trends or issues – like stockout increases or manufacturing and shipping delays – before they become problems.

Monitor your suppliers’ performance, as they’re key to your success. Your metrics will show longer lead times and rising defect rates as missed delivery deadlines or increased returns.

Ask your colleagues if there are hidden factors behind poor performance, such as new bottlenecks and communication breakdowns between production and inventory teams. Their feedback is essential as data won’t capture all your problems.

When you identify issues, use what you discover to change your KPIs or processes. Keep testing until you find the right approach to reduce costs, improve efficiency and boost sales.

The JIT system’s flexibility is its main advantage. Regularly check your KPIs to see that you’re hitting your targets. Look for incremental improvements to boost productivity and customer satisfaction and minimize costs and waste.

Using Pipedrive for just-in-time management

Pipedrive’s flexible and customizable features can support basic JIT processes natively, eliminating the need to invest in sophisticated and costly inventory management solutions. Integrations like MRPeasy further extend Pipedrive’s capabilities into production and stock control.

Here are four ways you can use Pipedrive for your JIT stock management system.

1. Project management for JIT implementation and beyond

Projects by Pipedrive helps you stay organized and track projects by turning complex workflows into clear, manageable steps.

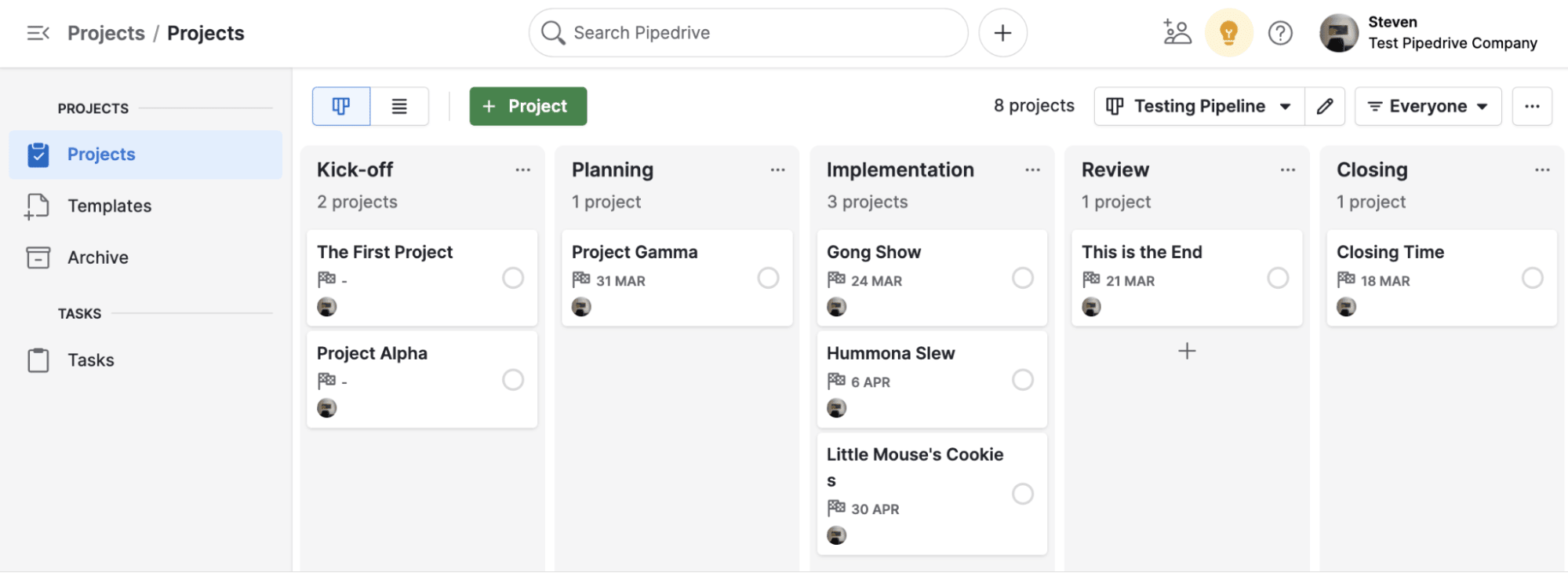

Kanban-style boards help you visualize your workflow by splitting projects into columns representing different stages. Cards in each column indicate individual tasks, project details or milestones, making it easy to track progress.

Here’s what a project board looks like in Pipedrive:

To set up a JIT implementation project:

-

Navigate to the Projects tab in Pipedrive and click on the “+ Project” button near the search bar

-

Fill in the project details. Give the project a title, start and end dates and a brief overview of the project goals. Assign a task owner – for instance, you or a coworker.

-

Decide on the number of stages. You can create three for a JIT implementation project – “Kick-off”, “Planning” and“Implementation”.

-

Create cards per task in each column, such as auditing your current stock at “Kick-off” and simplifying receiving and storing stock under “Planning”.

If a task requires more work, you can add subtasks to cards in Pipedrive. For example, to audit current stock, you could include subtasks like checking for overstocks, identifying slow-moving stock and running stock aging reports.

Assign each task or subtask to a colleague, letting them know what to do and when.

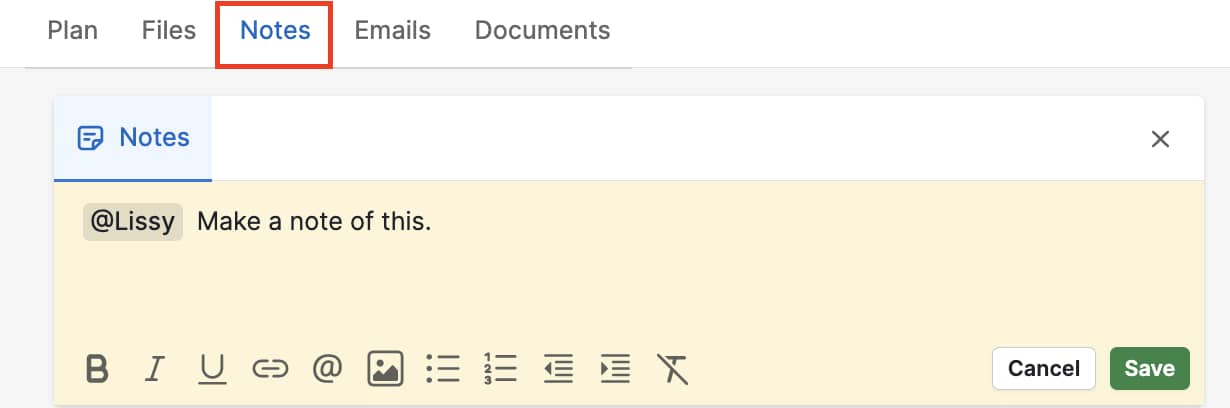

Team members can leave comments and questions for each other in cards. They can also use mentions (@username) to flag someone for help.

When a task is complete, mark it as done. Set an automation to let the project manager know so they can move the project on.

Project managers can see everyone’s progress by clicking on the Projects board.

You can also use Projects to:

-

Check your JIT system quarterly. For the first stage, gather performance KPIs and collect team feedback. For stage two, hold a senior management meeting to decide on action in stage two. Mark stage three as complete when you’ve carried out the recommendations.

-

Streamline ordering and production. When your sales team closes a deal, set up stages for finance to collect a payment, procurement to order raw materials and stock, assembly line to start manufacturing and dispatch to prepare shipping. Keep your salespeople in the loop at all times.

Pipedrive’s Projects helps streamline and organize the implementation of your JIT system, monitor its performance, deliver ongoing improvements and control the manufacturing process.

2. Cataloging with Pipedrive Products

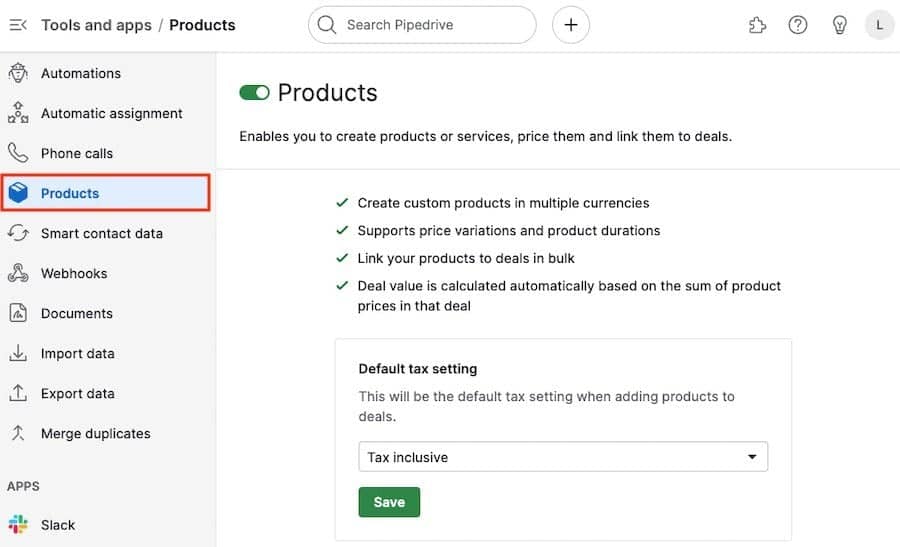

Pipedrive’s Products feature helps you create and manage a detailed catalog of your products and services, making inventory tracking and sales process optimization easier.

Here’s how to set it up.

Click “Enable Products” to activate the feature. This adds a Products tab to your navigation bar.

Go to the Products tab and click “+ Product”. Enter the product name, unit price and additional details.

Add these two custom fields to each product for inventory management purposes:

Then, save the product. You can also group products into categories for more effortless organization.

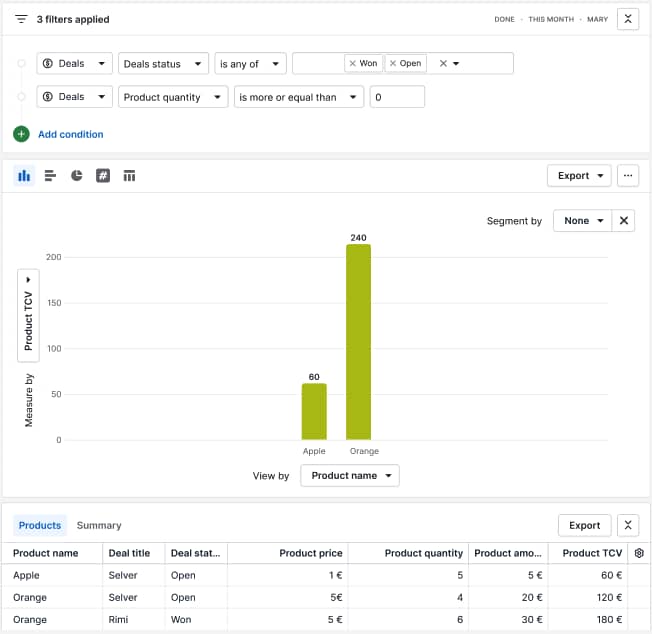

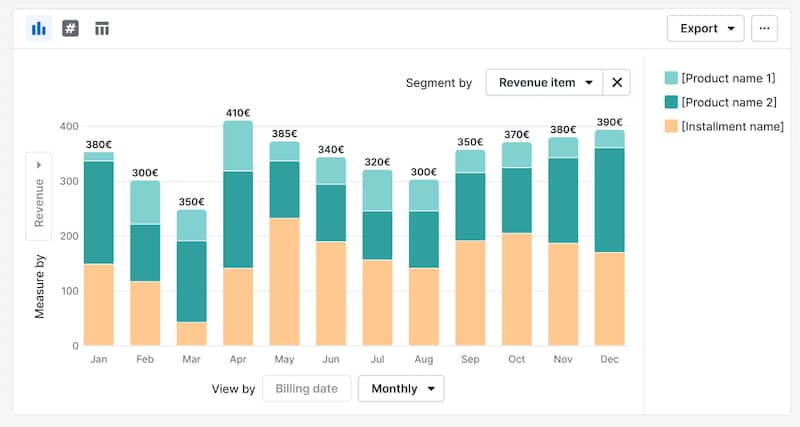

You can use Pipedrive’s Insights to run visual sales reports on the number of individual products sold.

To create a product report:

-

Go to Insights and click “+” > “Deal” > “Products”. Choose the timeframe you want to track.

-

From “Filters”, select “Deals”, then “Deals status” and finally “Won” in the field next to the “is any of”’ dropdown menu. If you want to filter by your ABC categorizations, select “Deals”, then “ABC” and “Won” in the field next to “is any of”.

You’ll see a visual graph for the sales of individual A products, plus a table with the product cost and the sale amount, to help you calculate profit.

Pipedrive’s Products shows how in demand and profitable each product and category is, letting you focus your sales efforts and JIT strategy more effectively.

3. Sales forecasting with Insights

Pipedrive’s Insights feature offers a deal revenue forecast report, enabling you to estimate future revenue by analyzing closed and pending deals. This forecast can help you plan your inventory needs based on expected sales.

Navigate to the Insights section in Pipedrive. Click the “+” icon, select “Report”, then choose “Revenue forecast” followed by “Deal revenue forecast”.

Track sales trends by product to see how much each generates monthly and spot high-demand products needing frequent reordering. Monitor products with low or declining sales and use this data to refine both your inventory and sales strategies. Then, decide whether to adjust your inventory, run a sales promotion or phase them out for good.

Although you should base your inventory strategy on customer sales with JIT, these forecasts give you and your suppliers valuable information on expected demand trends and help you plan resources effectively. Insights forecasts are particularly applicable to products with long lead times and seasonal demand variations.

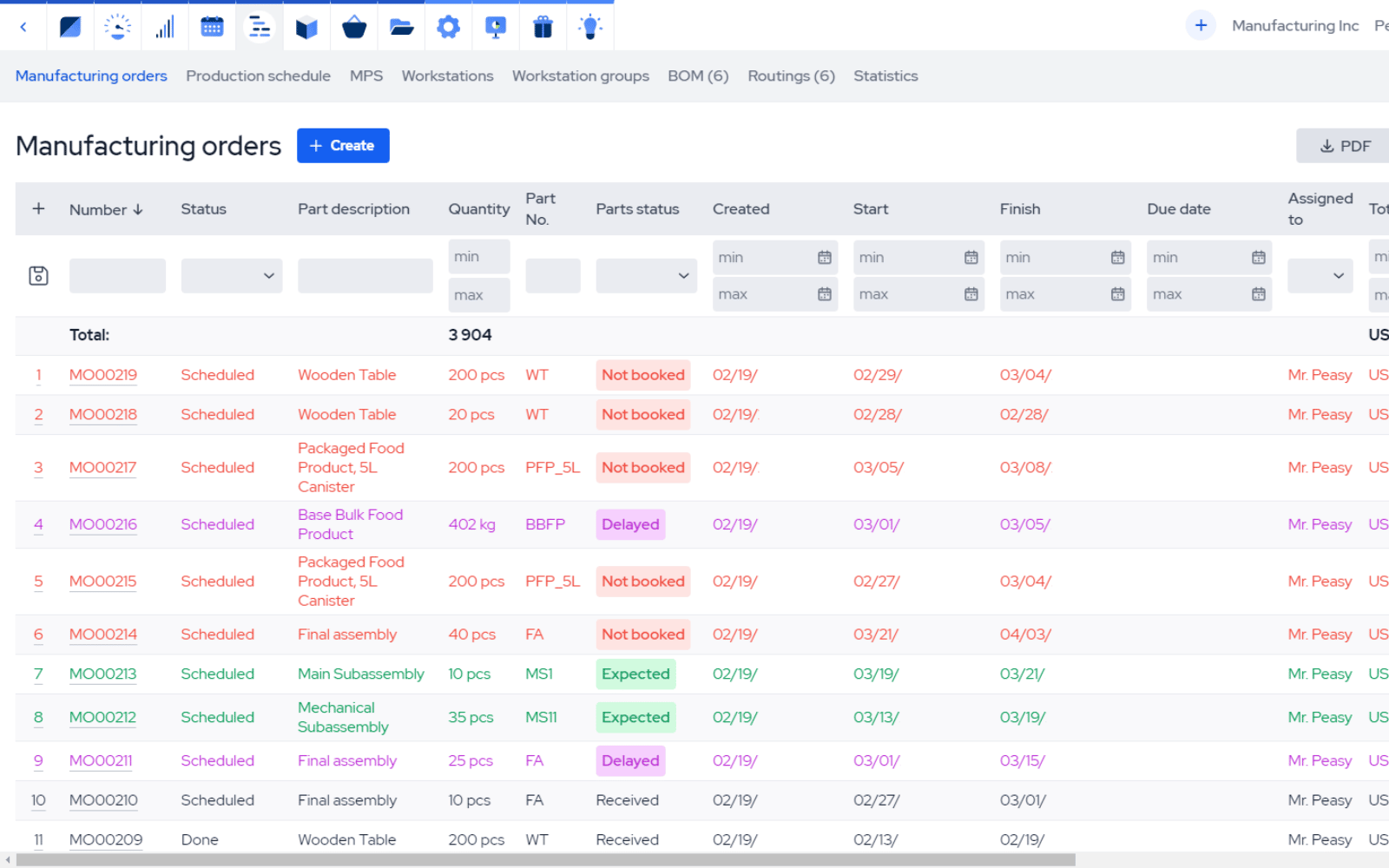

4. MRPeasy integration for smaller manufacturers

If you’re a small manufacturer and already use MRPeasy for JIT manufacturing and warehousing, you can integrate it directly into Pipedrive to automate and streamline your order-to-production process.

When one of your sales reps closes a deal in Pipedrive, MRPeasy automatically creates a customer order so your production and warehousing teams can get straight to work. When you’ve shipped the order, the deal updates in Pipedrive. Dispatchers can leave notes for your salespeople to update them on order progress.

Product and customer information sync seamlessly between the two apps, keeping your database consistent, accurate and up-to-date. To streamline your workflow, you can automate tasks in Pipedrive, including triggering production orders or updating stock levels sent to MRPeasy.

MRPEasy’s integration with Pipedrive connects your sales, production and dispatch teams, speeds up order processing and helps you keep your promises to customers.

Final thoughts

Just-in-time (JIT) inventory management helps you cut costs by reducing the stock you need to order and store. The tight supply chain management JIT provides means you can better meet consumer demands on quality and delivery deadlines.

Regularly monitoring your KPIs can help you spot further opportunities to improve efficiency and make your business more profitable and competitive.

You can use Pipedrive’s features and integrations to help you stay on top of your JIT program. From project management and product cataloging to revenue forecasting and production scheduling, you’ll have the necessary tools to keep your supply chain lean and responsive.

If Pipedrive is of interest and you'd like more information, please do make contact or take a look in more detail here.

Credit: Original article published here.